Shower Glass Selection Guide: Zero Explosion Risk + Permanent Scale Protection

Pain Point Solution:"Conventional shower glass = 1% explosion risk? We guarantee 0% spontaneous breakage! Nano-coating repels 90% limescale, anti-slip texture cuts fall risk by 80%."

📊 Shower Glass Product Matrix

| Category | Core Technology | Key Benefits | Top Applications |

|---|

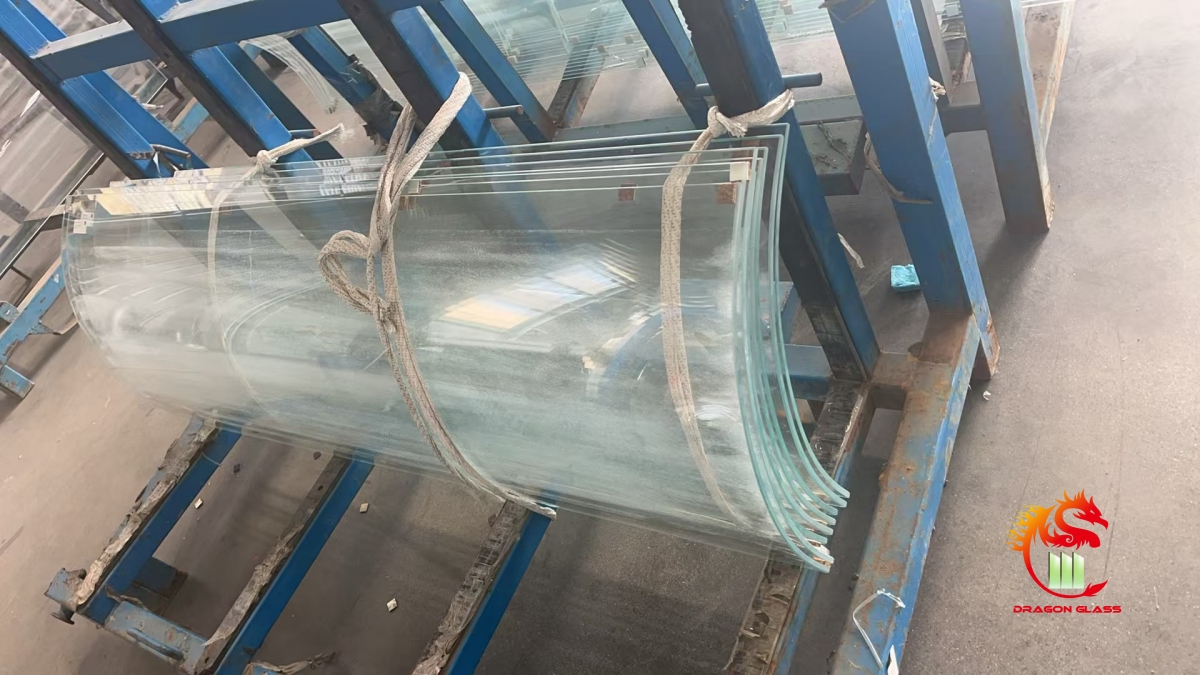

| Laminated Safety Glass | 5mm Tempered + 0.76mm PVB | Breakage rate ≤0.01% | Luxury hotels, nursing homes |

| Nano Easy-Clean Coating | SiO₂ Superhydrophobic Layer | 90% less scale, 50% cleaner saving | Hard water areas |

| Ultra-Clear Frameless | Low-Iron Glass (Fe₂O₃≤0.015%) | ≥91.5% light transmission | Designer boutiques |

| Anti-Slip Textured | Micro-Etched Surface (R10) | Wet friction coefficient ≥0.45 | Medical centers |

| Smart De-Fogging | ITO Heating Film + Thermostat | Clear view in 3s, 15W/㎡ consumption | Ski resorts, luxury spas |

![]()

![]()

![]()

🔍 Technology Deep Dive

1. Laminated Safety Glass: Unbreakable Promise

- Third-Party Certification:

▶ ANSI Z97.1 Impact Test: 2x higher than required

▶ Stress Test: 120MPa surface compression (CE EN 12150) - Commercial Solutions:

▶ Hospital Grade: 8mm glass + antimicrobial PVB

2. Nano Easy-Clean: Science Against Scale

- Lab Proof:

▶ Water Slide Angle: 8° vs 38° (ordinary glass)

▶ Scale Inhibition: 92% reduction after 300 cycles (ASTM D2486) - Hard Water Defense:

▶ Coating Durability: >10 years at 400ppm hardness (SGS test)

3. Ultra-Clear Frameless: Invisible Luxury

- Optical Superiority:

▶ Iron Content: 90% lower than standard glass

▶ UV Block: ≤14% transmission (museum conservation grade)

✅ Selection Algorithm

markdown复制1. Safety First

▶ Healthcare/elderly → Laminated + R10 anti-slip

▶ High traffic → 10mm thickness + EN14428 certified

2. Water Quality Matters

▶ Hard water (>180ppm) → Nano permanent coating

▶ Soft water → Hydrophilic layer

3. Design Priority

▶ Minimalist → Ultra-clear frameless (≥8mm)

▶ Privacy → Fritted patterns / Colored PVB