A Brief Discussion on Triple Silver Low-E Coated Glass Introduction

A Brief Discussion on Triple Silver Low-E Coated Glass

Introduction

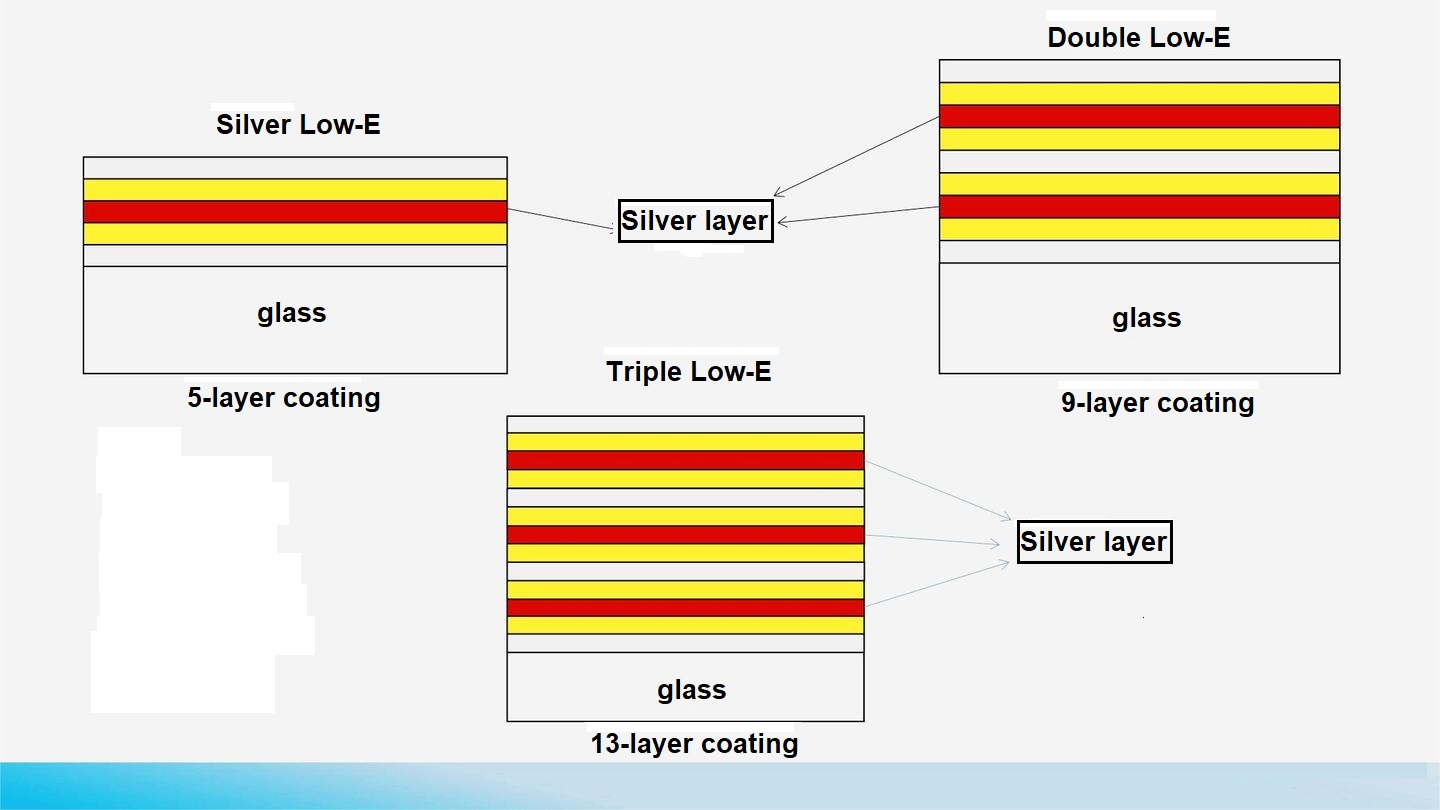

As global awareness of building energy efficiency grows, many countries have introduced policies to reduce energy consumption in buildings, leading to the rapid development and widespread application of low-emissivity (Low-E) coated glass. Over nearly 30 years of evolution, Low-E glass has progressed from single-silver to double-silver, and in recent years, to triple-silver Low-E glass.

Triple-silver Low-E glass offers higher visible light transmittance for better indoor daylighting, lower solar infrared heat transmittance, and lower heat transfer coefficients. It is widely recognized as the most energy-efficient and human-friendly architectural glass currently available. Its U-value is less than 1.65 W/(m²·K), and its shading coefficient is below 0.30, helping maintain a comfortable indoor temperature and environment.

1. Production Process of Triple Silver Coated Glass

Low-E glass is made by depositing multiple layers of metal or compound coatings onto the glass surface using vacuum magnetron sputtering equipment.

- Single-silver Low-E: 1 silver layer, structure: Glass / Dielectric Layer / Barrier Layer / Silver Layer / Barrier Layer / Dielectric Layer.

- Double-silver Low-E: 2 silver layers, structure: Glass / Dielectric / Barrier / Ag1 / Barrier / Dielectric / Barrier / Ag2 / Barrier / Dielectric.

- Triple-silver Low-E: 3 silver layers, structure: Glass / Base Dielectric Composite Layer / Ag1 / Barrier1 / Intermediate Dielectric Layer 1 / Ag2 / Barrier2 / Intermediate Dielectric Layer 2 / Ag3 / Barrier3 / Top Dielectric Layer 1 / Top Dielectric Layer 2.

Figure 1: Production Process Diagram – Not Displayed

[1] Glass Cleaning & Drying

↓

[2] Deposition of Base Dielectric Composite Layer

↓

[3] Deposition of 1st Ag (Silver) Layer

↓

[4] Deposition of 1st Barrier Layer

↓

[5] Deposition of 1st Intermediate Dielectric Composite Layer

↓

[6] Deposition of 2nd Ag Layer

↓

[7] Deposition of 2nd Barrier Layer

↓

[8] Deposition of 2nd Intermediate Dielectric Composite Layer

↓

[9] Deposition of 3rd Ag Layer

↓

[10] Deposition of 3rd Barrier Layer

↓

[11] Deposition of Top Dielectric Composite Layer 1

↓

[12] Deposition of Top Dielectric Composite Layer 2

↓

[13] Final Product: Triple Silver Low-E Coated Glass

Production Steps:

- Clean and dry the base glass, place it in the vacuum sputtering zone.

- Use dual-rotating cathodes and mid-frequency reactive magnetron sputtering to deposit base dielectric composite layers.

- Use planar or rotating cathodes with DC or pulsed DC sputtering to deposit the first Ag layer.

- Repeat the process for each barrier and dielectric layer until all three Ag layers and associated dielectric layers are deposited.

- Apply the final top dielectric layers using dual-rotating cathodes and mid-frequency sputtering.

The improved structure and method of the triple-silver Low-E glass significantly enhance its performance, providing lower emissivity, better selectivity, and more neutral indoor/outdoor appearance without interference colors. These properties allow broad application in both architectural and automotive glass.

2. Performance of Triple Silver Coated Glass

Low-E glass is designed to reflect far-infrared radiation while maintaining high transparency. It reduces indoor heat loss and maintains indoor temperature, offering energy-saving benefits.

Table 1: Optical Properties of Single, Double, and Triple Silver 6Low-E+12+6 IGU Glass – Not Displayed

| Low-E Type | Visible Light Transmittance (%) | Shading Coefficient (SC) | Solar Heat Gain Coefficient (SHGC / G-value) | U-value (W/m²·K) |

|---|---|---|---|---|

| Single Silver Low-E | 75 | 0.65 | 0.58 | ~2.0 |

| Double Silver Low-E | 70 | 0.40 | 0.36 | ~1.8 |

| Triple Silver Low-E | 68–72 | ≤0.30 | ≤0.28 | ≤1.65 |

📝 Notes:

- Glass configuration for all: 6 mm Low-E + 12 mm air gap + 6 mm clear glass (IGU).

- Triple-silver glass shows best solar control with minimal visible color shift and improved comfort.

- The U-value for triple-silver meets strict energy-saving standards in cold and hot climates.

From Table 1, we observe that triple-silver IGU glass maintains high solar transmittance while achieving low shading coefficients and G-values. Unlike double-silver glass, which can exhibit red or green color shifts under different viewing angles, triple-silver glass maintains visual neutrality, improving the aesthetic appearance of buildings.

The use of advanced manufacturing ensures each nano-layer’s thickness variation is less than 1% (precision up to 0.1 nm), effectively eliminating interference colors—a major challenge in coated glass production.

Visually, double-silver glass often appears in dark gray or blue tones, which may reduce comfort. In contrast, triple-silver glass displays a pleasant blue-green hue, improving visual comfort.

Thermally, triple-silver Low-E glass offers significantly better insulation at night by reducing heat radiation and convection. Compared to ordinary glass, it can improve energy efficiency by over 80%.

3. Technical Features of Triple Silver Coated Glass

(1) Coating Performance

Advanced technology ensures layer thickness variation <1%, precision up to 0.1 nm.

U-value <1.65 W/(m²·K), shading coefficient 0.30 – top-tier energy-saving performance.

(2) Coating Structure

First to propose a triple-functional-layer structure:

Glass / Base Dielectric Composite Layer / Ag1 / Barrier1 / Intermediate Dielectric Layer 1 / Ag2 / Barrier2 / Intermediate Dielectric Layer 2 / Ag3 / Barrier3 / Top Dielectric Composite Layers.

This represents a major structural advancement over mainstream global products.

(3) Coating Materials

The use of advanced dielectric materials—TiO₂·ZnSnOX, SnO₂, ZnO, SiO₂·Ta₂O₅, Bi₂O₃·Al₂O₃, ZnAl, Nb₂O₅, Si₃N₄, AZO—significantly lowers costs and enhances key performance indicators.

(4) Coating Process Highlights

- Adding silver and dielectric layers improves selection coefficients without sacrificing transmittance or appearance.

- Solving the challenge of reduced transmittance and interference color during Ag layer thickening via: Better film layer design (optimized material ratios around Ag layers). Thinner and denser Ag and barrier layers.

- Dielectric composite layers reduce reflection, bond well to glass, relieve internal stress, and influence scratch, wear, and corrosion resistance.

Conclusion

Triple-silver Low-E coated glass is poised to become the mainstream product for architectural curtain walls worldwide. Its broad market potential and significant energy-saving performance are driving innovation in glass manufacturing and raw materials. Its adoption will accelerate development in energy-efficient buildings and benefit the entire industry.